LPCB spotlight on Tommy Trybus

You wouldn’t buy a car if it hadn’t been properly tested in advance, so why should security products be any different?

1. How do you explain your day-to-day work to your friends and family?

A professional burglar, and if they want to know more; that I test and certify security products to ensure they deliver the required performance, should they ever be attacked. Most people don’t realise the job exists, but you wouldn’t buy a car if it hadn’t been properly tested in advance, so why should security products be any different?

2. What motivates you most about your work?

I enjoy the variety of the work. Although it’s a bit of a cliché, every day is different. A big motivation is knowing that the products that we test and certify genuinely make a difference, helping to protect people and property. It is great when I recognise products we have certified when out and about during day-to-day life, knowing we have played a part in their development.

3. How has your role evolved over the time you’ve been at BRE?

I started out mainly involved in the labs testing security products. These days, alongside product testing, I am the project lead for a large research programme and also support our business development work, through exhibitions and conferences in the UK and internationally (when we are able to travel) and as part of the team developing our standards to ensure they are up to date and remain relevant to current threats.

4. When you were studying for your degree, how did you envisage your career panning out?

I did a mechanical engineering degree and envisaged that I would end up designing or making things – at one point during my degree, I was going down the route of medical implant design.

However, I have been at BRE working within the Security Team since graduating and, although in our team we do not generally make things, we have to use our technical knowledge of materials and construction methods to work out the best way to ‘deconstruct’ the security products put in front of us.

One misconception is that we spend all day smashing things up in the lab as some kind of stress relief. There is a lot more to the testing process than that.

5. What is the biggest misconception about your work?

There’s two. Firstly, that we spend all day smashing things up in the lab as some kind of stress relief. There is a lot more to the testing process than that, and frankly it would be extremely tiring if that was the case.

Secondly, we often get asked questions like ‘why don’t you just pick up a thermal lance or petrol disc grinder?’. The standards we test products to generally have a range of different tool kits which suit the alternative threats that different products are designed to mitigate.

It is not just a case of trying to gain entry into something using any tools you desire. A residential door is designed to resist completely different attack tools and methodologies compared to a bank vault – you are unlikely to see a domestic burglar trying to break into a property using a petrol disc grinder and diamond core drilling rig!

6.What one industry change would you like to see to help you in your role?

Considering that 95% of products submitted for testing fail to offer the performance declared or desired, I would like to see wider recognition of the benefits of buying and using certified security products, and the assurance they can deliver to end users and risk holders when it comes to keeping people and property safe.

It could be that legislation such as the Protect Duty may stimulate some change in sectors where the benefits of certified security products aren’t currently fully recognised.

7. Of all your experiences and achievements in the security team to date, which one are you most proud of, and why?

I have had the privilege to work on a number of iconic and interesting projects to date. However, the experience I am most proud of is from a few years ago, when I was first invited to present my research findings at a government conference. I was delighted to know my work was being recognised by my peers, clients and industry experts.

8. Sum up working at BRE in three words.

Exciting, rewarding, innovative.

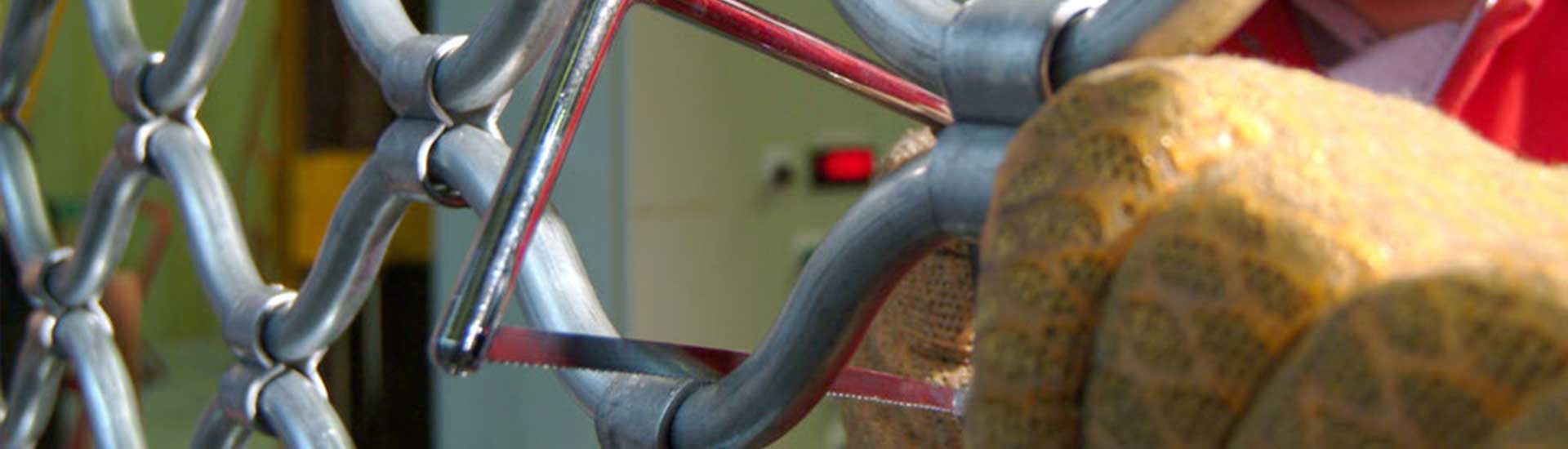

LPCB Security Product Testing Video

Our third party certification of fire and security equipment is underpinned by robust testing and evaluation of products and supporting documentation and auditing of clients supporting processes. BRE’s forced entry testing of physical security equipment is renowned around the world, by a growing number of Governments, regulators, multinational end-users, police and insurers.

LPCB product certification process

What is product certification?

Certification (or approval) is independent third party confirmation that a product or system meets and continues to meet the appropriate standard. BRE Global offers independent third party certification to existing British, European, International and its own Loss Prevention Standards (LPSs) or Schedules of Requirements

Be first to know the latest LPCB news and get exclusive insight from our industry experts each month

Share

Tags

Latest news from LPCB

The role of third-party certification in installing gas extinguishing & condensed aerosol systems

The journey from research to test standard for video flame detectors

Refreshed RedBookLive website now live

LPCB debuts its Live Testing Lab at The Security Event 2024