The journey from research to test standard for video flame detectors

Developing Standards for Video Flame Detectors

These types of detectors suit large open spaces situated at greater distances from the fire and operate effectively in challenging environments like departure lounges, aircraft hangars, oil rigs, waste processing facilities, tunnels, and factories. They are more effective than traditional fire detectors in such applications as they do not require the smoke or heat from the fires to reach the actual detectors.

Video fire detectors use cameras to monitor protected spaces and use sophisticated analytical algorithms to process any images obtained and identify the presence of smoke and/or flame. For many years, due to their complexity and variable functionality, there were no defined and robust methods for assessing the capabilities of these detectors to ensure that they were suitable for the service environment.

Whilst international standards for video fire detectors exist, these are often drafted following discussions and without the necessary research required to develop a robust and comprehensive product test standard.

Formation of a collaborative research group, including the Fire Industry Association, BRE and fire detector manufacturers, focused on the challenges presented by the two main technology types – video flame detectors (VFD) and video smoke detectors (VSD). Using the principles from the EN 54 series of standards (for assessing fire detectors) as the basis, the group explored reproducible test methods for assessing the “benchmark” performance capabilities of these products. Additionally, investigation of suitable operational performance tests established the distance at which these detectors could reliably detect a fire, to identify their performance limitations.

Once the group developed the benchmark and operational performance test methods, these were trialled on a number of manufacturers’ products to identify suitable pass/fail criteria. This led to a briefing paper summarising the work, available here.

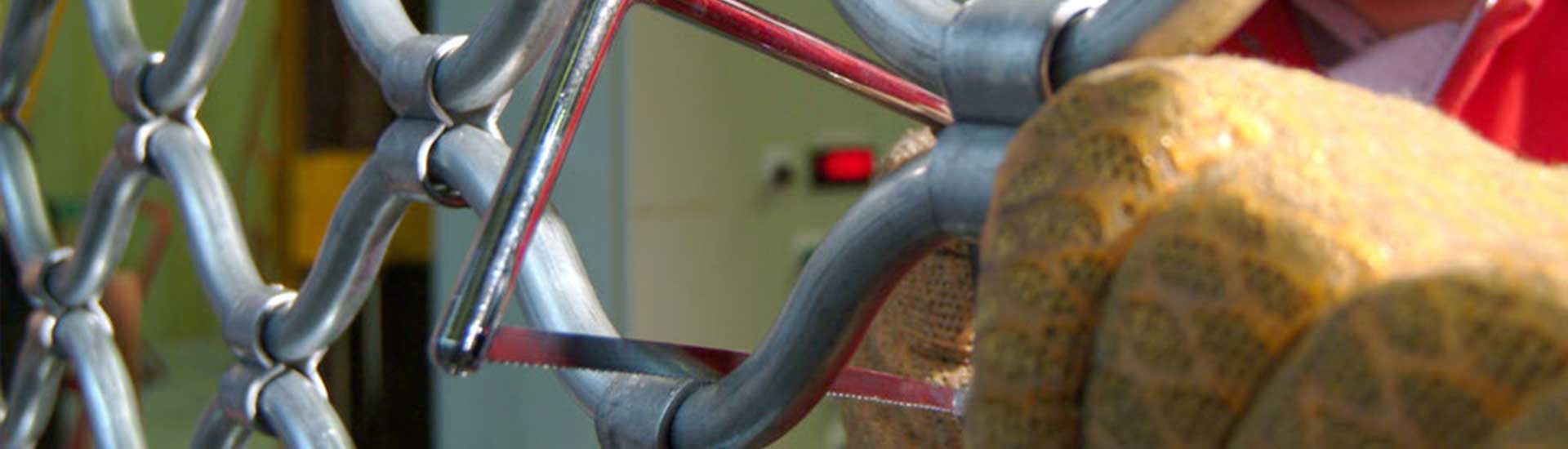

Following this work, a group of manufacturers were keen to develop a test standard specifically for video flame detectors. Further research work was performed with this industry group, that together with the Fire Industry Association, developed tests based on false alarms commonly observed in the service environment. The group designed the tests specifically to demonstrate no false alarms due to heat sources in the field of view of the camera, light saturation and sunlight reflecting off water.

The group then worked to develop suitable test methods for these and used EN 54-10:2002 for Point type flame detectors as the basis for all other tests. The accumulation of this work has resulted in LPS 1976: Issue 1.1 for video flame detectors and video flame detection systems. Video flame detectors can be stand-alone, in which case the sensor, analytics and decision-making systems are all within the device. Video flame detection systems are then distributed - where the critical analytics decision-making processes work remotely from the sensing device/s.

LPS 1976 specifies requirements, test methods and performance criteria for these types of detectors which specifically detect changes in video images characterised by the properties of flames generated during the combustion of carbon-based materials. Detectors complying with LPS 1976 will operate as primary systems, offering comparable levels of protection as other fire detectors to EN 54 standards. By following the comprehensive validation journey that has led to this standard, products complying with it will offer the greatest level of protection in the service environment in the future.

Visit RedBookLive to search listed products, companies and download Loss Prevention Standards, including LPS 1976: Issue 1.1.

We would like to take this opportunity to thank the partners in this work, listed in the briefing paper and in the LPS 1976 standard, but particularly the Fire Industry Association, which has been a vital partner from the outset of this work.

Share

The role of third-party certification in installing gas extinguishing & condensed aerosol systems

The journey from research to test standard for video flame detectors

Refreshed RedBookLive website now live

LPCB debuts its Live Testing Lab at The Security Event 2024